Materials, Techniques, Evolutions

From our initial Viberg Factory Tour journal entry almost four years ago, what follows is a long overdue update on a partnership and a stewardship of this manufacturing brand. From our launch of six make-ups with this cult collector favorite to now having well over thirty exclusive collaborations at any given time along with our shared core identities and values towards design, production, and visions about the business, we continue to evolve through working in close concert. In that period of time, with a footwear-first position to wardrobes, our educational service approach, and collectable curations, we have grown into Viberg’s largest stocklist worldwide, by a considerable margin.

A significant piece of this is because we’re passionate about footwear at the rebuildable and hand grade level, coupled with a corresponding ethos of honoring heritage and legacy by progressing the product at all levels, while not compromising the integrity. Viberg’s aim has been the application of fresh eyes in re-working historical pieces into footwear that will persist both durably and stylistically, as not everything made yesterday was necessarily better, and an established framework can be honored and respected through improvements. Viberg has proved this through generations, and this ability to more aggressively advance tradition is enabled by having design and production all wrapped into one enterprise and under one roof. Division Road very much shares this attitude of taking vintage inspirations to the next level by reworking materials, designs, and fit to up-produce originals while always reflecting the soul of the archetype, which affords us more effective and impactful collaborations.

Part of Viberg’s legacy is an identity immersed in crafting fully rebuildable footwear that offers the potential of a lifetime in one pair of boots. We use the fully rebuildable term often, and what it really means is the ability for the maker to rebuild from the constructed insole down, when performing a resole or repair service. This is made possible by using materials that are of a weight that breaks in rather than breaks down, and assembling via time honored techniques employed by skilled and trained craftspeople. These are components that are indistinguishable from the exterior of the product and can only be detected after years of use. This re-buildability is also independent from construction type. Goodyear welting and stitchdown construction are methods, but they do not necessarily denote quality or longevity. In the same way, not all wood framed houses are created equal whether it be the wood used, spacing, or craftspeople; both a house and a boot are living creations that will either stand the trials of time and conditions, or will wither into the ground.

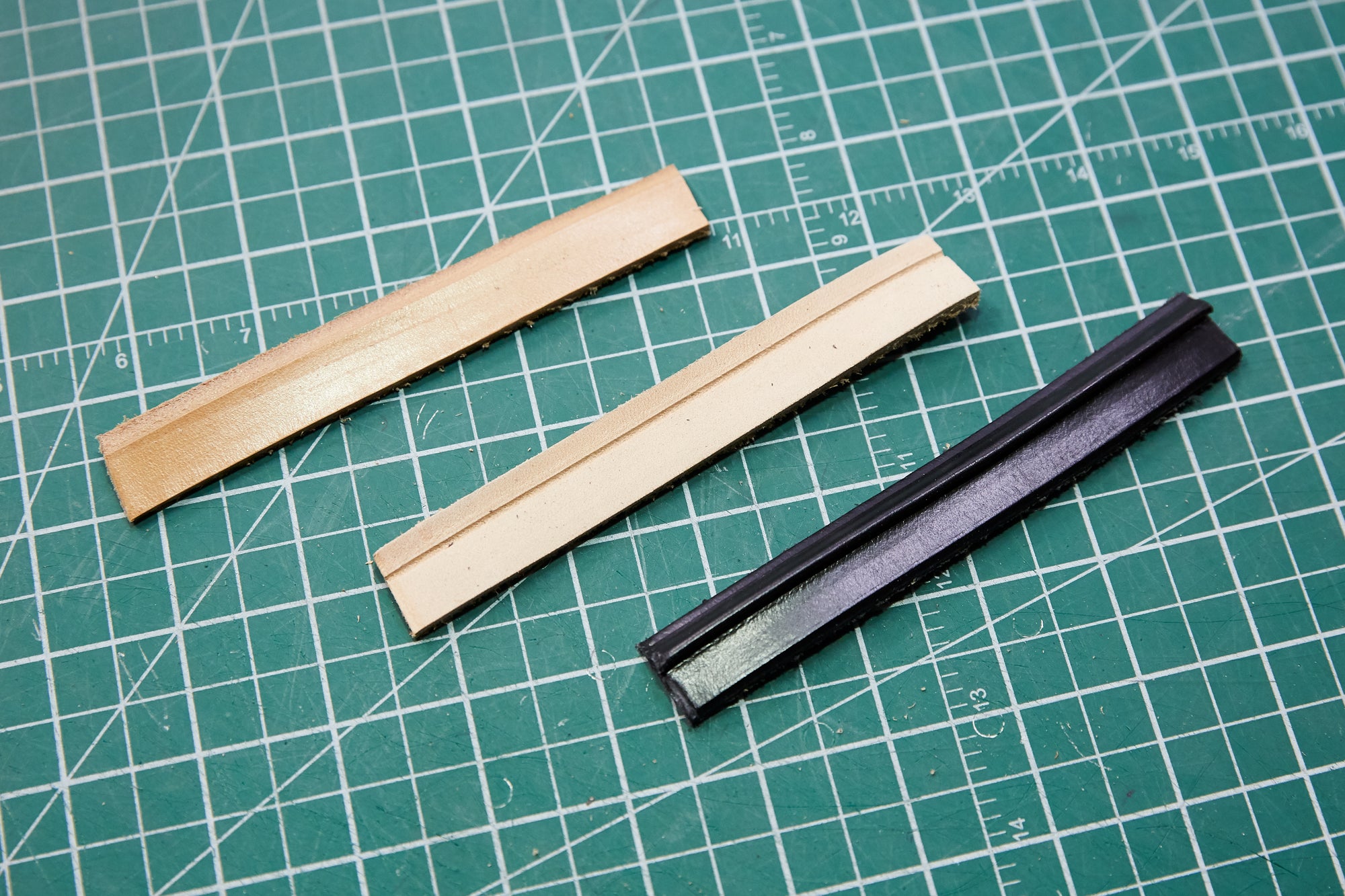

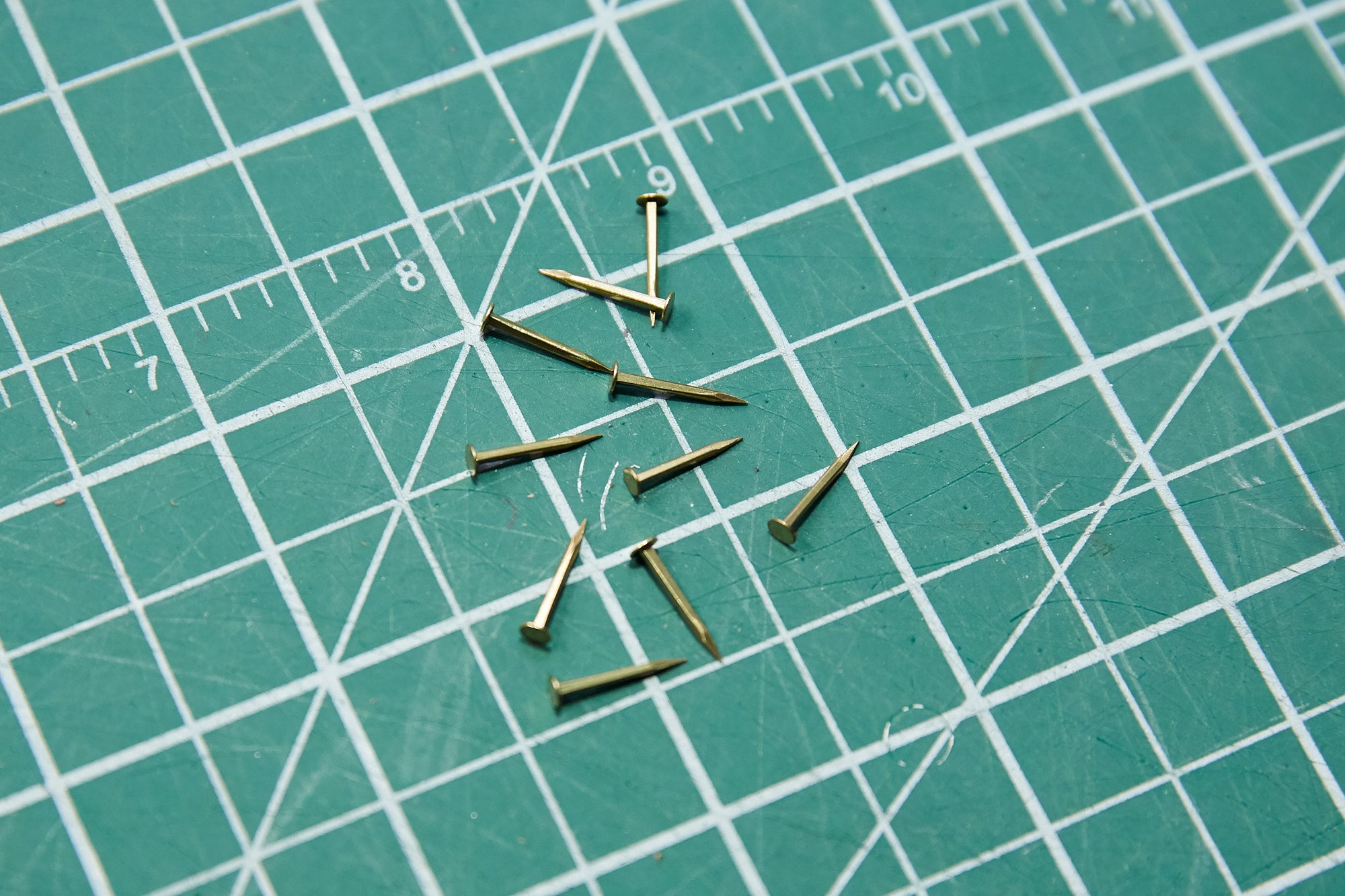

The Viberg journey from solely existing as a premium work boot maker to standing on the intersection of fashion and heritage has been a fringe movement. While always focused on aesthetics, a big portion of the advancement of the brand and product has taken place inside the build and within the processes of manufacturing. Viberg has constantly searched for the best materials that can be used, from brass nails from Japan and staples from the UK where most makers use steel, to the finest oak pit tanned insole and midsole leathers from Spain, to evolving stitchdown with cork fillings and developing a proprietary engineered wood shank to replace the old steel shanks.

These endeavors were instituted to produce a more natural product throughout, and the result is footwear that is subtly lighter with a greater degree of molding potential, all the while performing better in all conditions for the long-haul. To constantly invest in these improvements that are not apparent from the exterior and are challenging to leverage through communication shows a core virtue of pridefully making the best footwear possible within their walls, giving customers far more value than the competitors can even conceive of offering, all whilst advancing considered, enriched aesthetic design.

There are many examples of Viberg’s well-measured progress, some of which have been contrary to the opinions of what they were or should be by a core audience. When Viberg started to move into Goodyear welting from their more commonly associated stitchdown construction, there was quite an upheaval within the community, and understandably so, as many heritage enthusiasts have seen their favored brands cheapen product quality while using the same bellwether language when describing a product’s method of manufacturing, despite an inferiority to previous eras and productions. However, this transition by Viberg was not in an attempt to achieve massive scale, mislead, or a nefarious business strategy, but rather to improve some long-term, planned offerings and to have wider capabilities in order to do so.

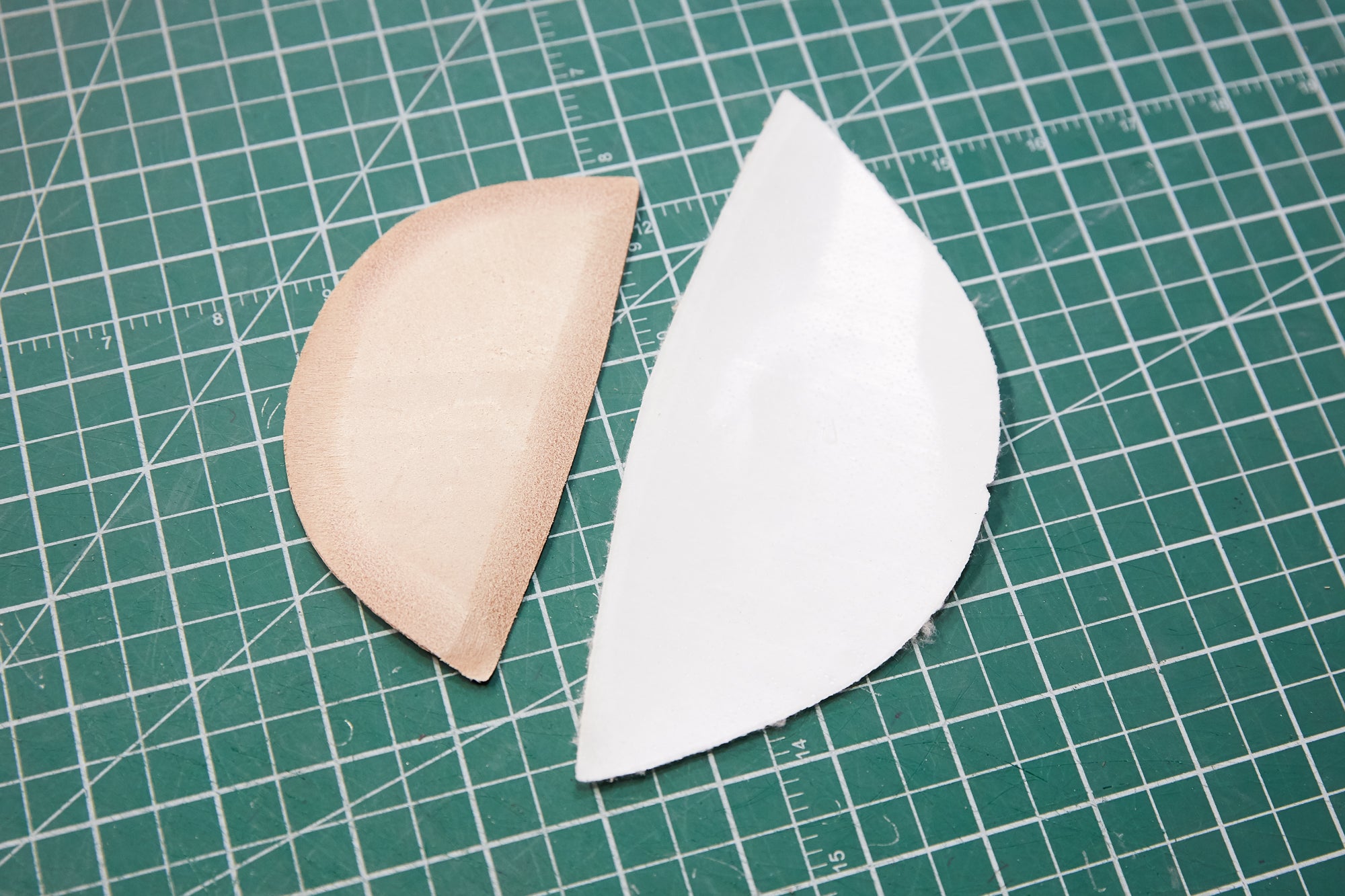

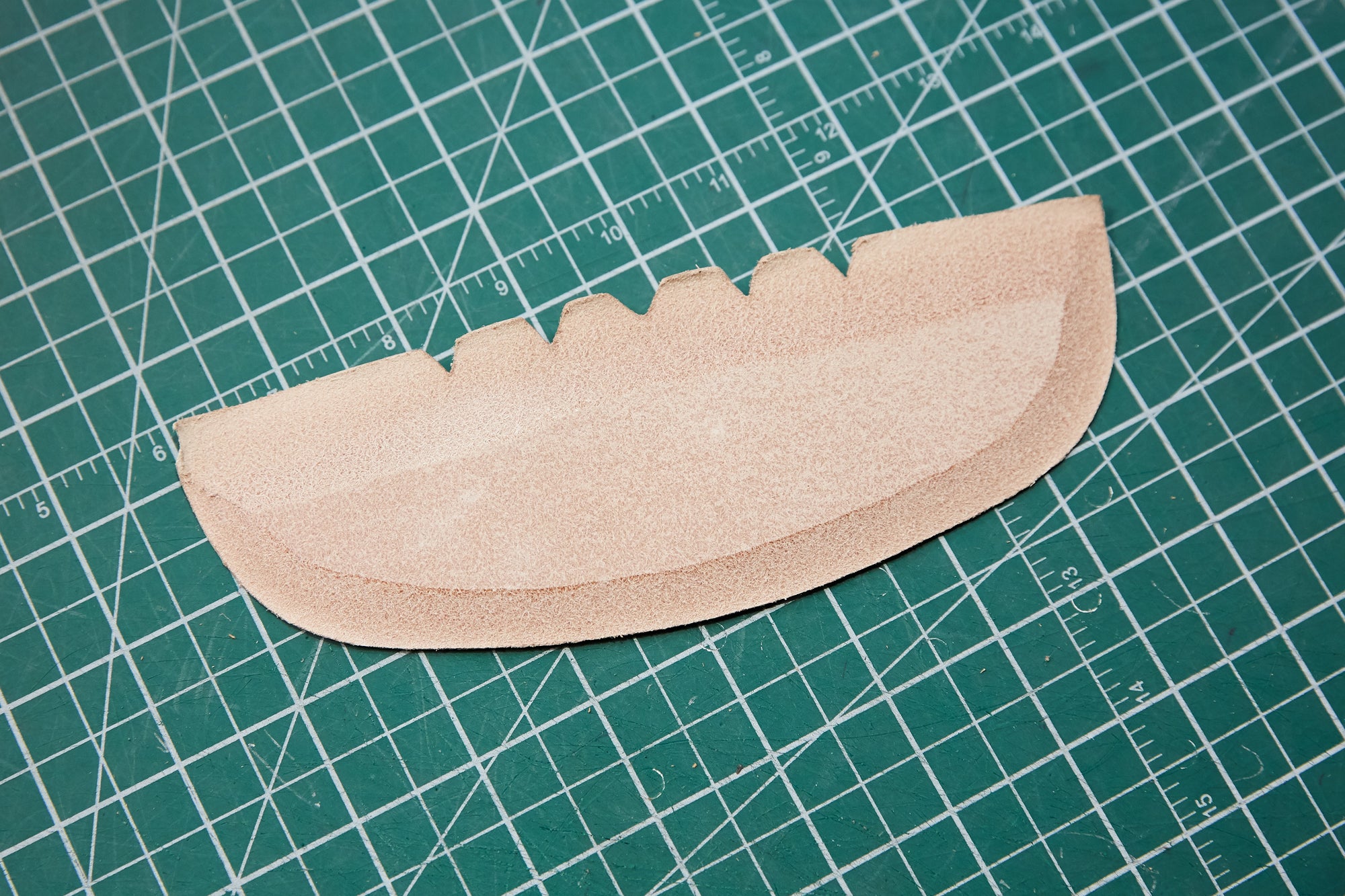

In true Viberg fashion, they drew upon their history first via their founding as a goodyear welting and nail-down boot maker, and a full generation before stitchdown production was introduced at Viberg in the 60-70’s, their logging and firefighting boot productions. Contrary to public opinion about the matter, Viberg’s legacy is as much a goodyear welt as a stitchdown footwear manufacturer. When re-introducing this type of construction, Brett did so with a desire to return to the highest proficiency of traditional welting, which harnesses components and steps utilized by only a few makers in today’s era. This involves using channeled insoles, which was only feasible after hunting for, purchasing, and rebuilding three WWI machines that cut a durable, single piece oak tanned leather insole, rather than the more common glued gemming construction used today. This actually added multiple steps to the process rather than streamlining their goodyear welting, but resulted in a superior product on another level entirely when compared to many other welted footwear producers. Furthering this methodology, Viberg uses improved and heavier materials in contrast to other makers who still employ traditional welting, thus offering workwear durability for a superior product when measured on resilience and longevity.

The core reasoning of adding goodyear welting was that it allowed Brett to explore styles and execute patterns with a higher level of refinement and streamlined aesthetic when juxtaposed to what stitchdown could offer. This included the Derby shoe, which was brought back from Edwin’s drafts from the 30’s, the wholecut Chelsea that was developed over nine pattern iterations and required the addition of two machines and four years of invested time to develop the perfected version, and finally the well-regarded wholecut slipper, which also has taken the community by storm as an understated, vintage-inspired casual shoe that’s almost become a default must-have for any collector. In addition, we have our own exclusive developments with Viberg using Goodyear welting on our Shelby Sharp and Pinky Blinders, which have been iterations on newly afforded patterns, and the completely original Hiking Hunter that combines patterns from several eras for a fully functional, outdoor-to-street hallmark boot that provides as much utility as it does style.

Do not let this veneration for goodyear welting be confused with putting stitchdown in the corner, as the evolutions in that construction also have been improved through completely reworking key components from exclusive developments and constant sourcing and testing, along with adapting production steps accordingly to offer a more flexible and moldable product that keeps the same guts-out, combined aesthetic of the sleek and rugged. Always looking to evolve to a more clean-cut result that uses the best materials, stitchdown construction remains the primary production type on the iconic Service Boot, and is used for landmark styles by default like the Engineer, Chukka, and our treasured Bobcat that we re-debuted in a collection build make-up for our launch and capsule collection in 2016.

We’ve communicated ad nauseum about Viberg’s approach to sourcing leather, and it’s clear this extends well beyond the upper. Yet, it’s important to recognize Viberg special orders all of their leathers in full weight, wherever possible, for hides that almost any other maker would balk at touching. There is a big difference in the performance of a full-grain, full weight hide to one that has been split down. Fundamentally, this is protection inherent to the animal itself afforded by natural evolution; meaning, the hide is the original full waterproof skin of the cow, horse, or camel, then enhanced through tanning with additional ingredients that offer a higher level of preservation and durability, concocted to allow graceful aging in their second life.

In conclusion, we align with Viberg’s goal to simply make the best boots and shoes in the world and it is at the core of why we work so closely with them and continue to acquire more and more institutional knowledge to translate to our clients and community. Our collaboration approach is simple: we look to utilize the parameters provided by a craftsman's experience with materials in production, and by using a co-design vision we work to create original reinterpretations that speak to us and our customers. There is a lot of thought, conversation, and effort that goes into every single detail of these projects. In that vein, we are pleased to present another cross-collaboration Shelby Sharp with blacked out details that allow the true character and qualities of this exclusive pattern to come through with heightened consideration. Designed in concert and paired with a fresh military archive MotivMfg capsule collection, this week, we wish to honor the present and past, with a content feature for contemplative consumption.

Viberg x Division Road Waxed Black Horsebutt Shelby Sharp Release: Friday, June 12th at 10am PT

PostScript - This update is a long-time coming and includes a preview of our renewed direction toward video, which we hope you’ll enjoy and find to be an elucidative tool in our implementation strategy. Stay tuned for more developments and evolutions in our service approach, company position, and virtual and in-store presentation; this is but a preview of exciting projects to come.